Exploring the Benefits and Applications of Chemical Resistant Control Cable

Introduction:

In various industries such as manufacturing, oil and gas, and mining, the need for reliable and durable control cables that can withstand harsh environments, including exposure to chemicals, is crucial. Chemical resistant control cables are specifically designed to meet this requirement, offering superior performance and longevity in challenging conditions. This article will delve into the features, benefits, and applications of chemical resistant control cables, shedding light on their importance in modern industrial settings.

Features of Chemical Resistant Control Cable:

Chemical resistant control cables are engineered with a range of features that enable them to withstand exposure to a variety of chemicals and substances. Some key features of these cables include:

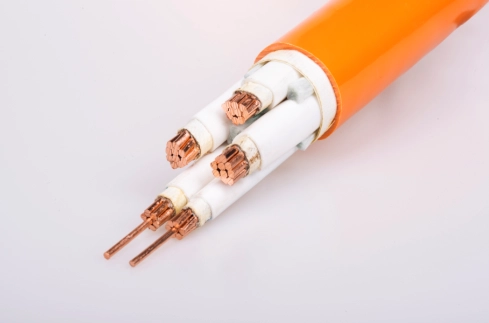

1. Specialized Jacket Material: Chemical resistant control cables are typically constructed using specialized jacket materials that provide protection against corrosive chemicals, oils, solvents, and other substances. Common jacket materials include PVC, polyethylene, fluoropolymers, and thermoplastic elastomers, each offering varying levels of resistance to chemicals.

2. Insulation Materials: In addition to the jacket material, the insulation of chemical resistant control cables is also designed to resist chemical degradation. Insulation materials such as polyethylene, polypropylene, and cross-linked polyethylene (XLPE) are commonly used to provide excellent electrical insulation properties while withstanding exposure to chemicals.

3. Shielding Options: To ensure signal integrity and protection against electromagnetic interference (EMI), chemical resistant control cables may feature shielding options such as foil shields, braided shields, or a combination of both. Shielding helps to maintain the integrity of control signals transmitted through the cable, even in the presence of chemical exposure.

4. Temperature Resistance: Chemical resistant control cables are often designed to withstand a wide range of temperatures, from extreme cold to high heat. This temperature resistance ensures that the cables remain functional and reliable in environments where temperature fluctuations are common.

5. Mechanical Strength: To withstand the rigors of industrial applications, chemical resistant control cables are built with a focus on mechanical strength. They are resistant to abrasion, impact, and bending, ensuring long-term durability and reliability in demanding environments.

Power Cable For Sale of Chemical Resistant Control Cable:

The utilization of chemical resistant control cables offers a myriad of benefits for industries where exposure to chemicals is a common occurrence. Some of the key benefits include:

1. Enhanced Durability: Chemical resistant control cables are built to last in harsh environments where exposure to chemicals can degrade standard cables quickly. The specialized materials used in their construction provide enhanced durability, ensuring a longer service life and reduced maintenance costs.

2. Reliable Performance: By withstanding chemical exposure, these cables maintain their performance and signal integrity over time, leading to consistent and reliable operation of control systems. This reliability is crucial in industries where downtime can result in significant financial losses.

3. Safety: Chemical resistant control cables contribute to a safer work environment by reducing the risk of electrical failures or malfunctions due to chemical exposure. This helps prevent accidents, injuries, and hazardous situations that can arise from cable degradation.

4. Cost-Effectiveness: While chemical resistant control cables may have a higher upfront cost compared to standard cables, their long-term durability and reliability result in cost savings over time. Reduced maintenance, replacement, and downtime expenses make them a cost-effective investment for industrial applications.

5. Versatility: Chemical resistant control cables are available in a variety of configurations, including multi-conductor, multi-pair, and composite cables, to suit different application requirements. They can be customized with specific jacket materials, insulation types, and shielding options to meet the needs of diverse industries.

Applications of Chemical Resistant Control Cable:

Chemical resistant control cables find applications across a wide range of industries where protection against chemical exposure is essential. Some common applications include:

1. Manufacturing: In manufacturing facilities where chemicals are used in production processes, chemical resistant control cables are employed to ensure reliable operation of machinery, conveyors, and automated systems. These cables help maintain control signals and power distribution in the presence of chemical vapors or spills.

2. Oil and Gas: The oil and gas industry relies on chemical resistant control cables to provide connectivity and control in drilling rigs, refineries, pipelines, and other critical infrastructure. These cables withstand exposure to hydrocarbons, corrosive fluids, and other chemicals commonly encountered in the industry.

3. Mining: Mining operations expose cables to abrasive materials, moisture, and chemicals present in the mining environment. Chemical resistant control cables are used in mining equipment, conveyors, and processing plants to ensure uninterrupted communication and control of machinery in these challenging conditions.

4. Chemical Processing: Within chemical processing plants, where a wide range of corrosive chemicals are handled, chemical resistant control cables play a vital role in maintaining operational efficiency and safety. These cables are used in control panels, sensors, pumps, and instrumentation systems throughout the facility.

5. Water Treatment: Water treatment facilities utilize chemical resistant control cables to monitor and control the treatment processes, including chemical dosing, filtration, and disinfection. These cables are crucial for ensuring the reliable operation of pumps, valves, and sensors in water treatment systems.

Conclusion:

Chemical resistant control cables are indispensable components in industrial environments where exposure to chemicals can compromise the performance and longevity of standard cables. With their specialized construction, durability, and resistance to chemical degradation, these cables offer reliable connectivity and control in challenging conditions. By understanding the features, benefits, and applications of chemical resistant control cables, industries can make informed decisions when selecting cables for their specific needs. As technology continues to advance, the development of innovative materials and designs for chemical resistant control cables will further enhance their performance and reliability in diverse industrial settings.